core technology

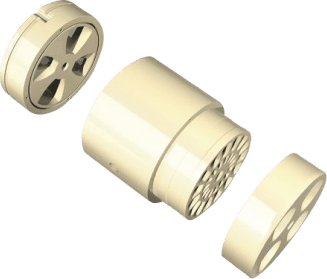

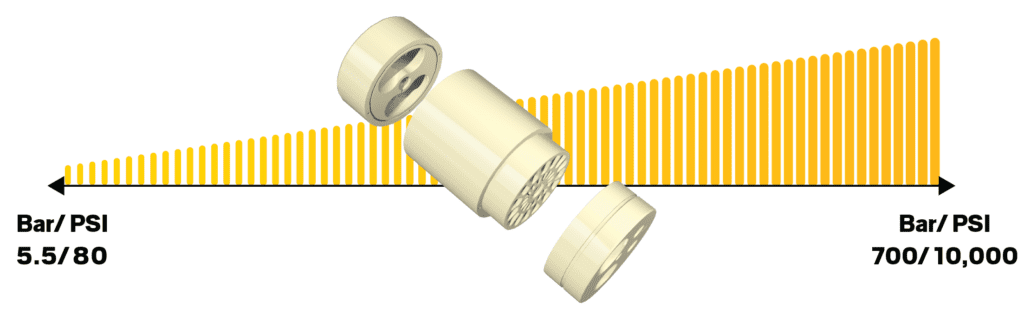

Our pressure exchanger technology is at the heart of many of our products and uses a ceramic rotor to efficiently capture and transfer pressure energy. When the PX® Pressure Exchanger® first entered the market over 30 years ago as an energy saving solution for the seawater reverse osmosis (SWRO) desalination industry, it was a game-changing technology that made the SWRO treatment process commercially viable. Today, many industries can benefit from using the PX to improve performance and environmental sustainability, lowering costs, saving energy, and minimizing emissions. This versatile technology is ideal for a wide range of pressure ratings (from low to ultra-high) and can handle both liquid and gas.

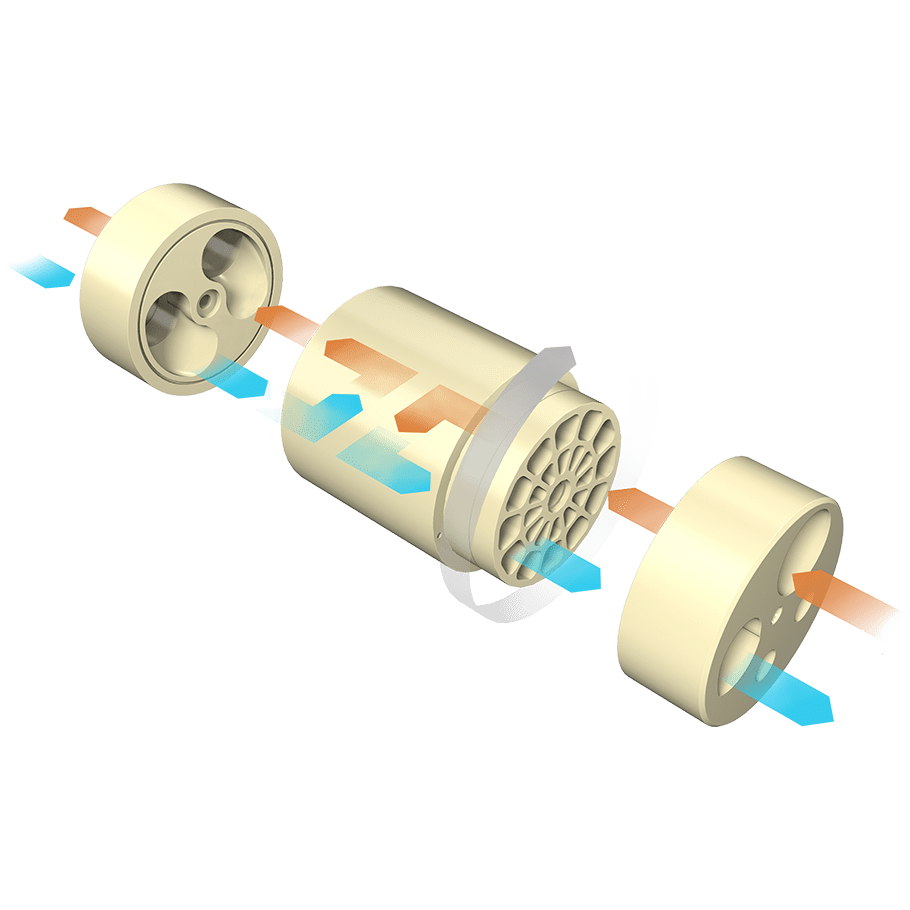

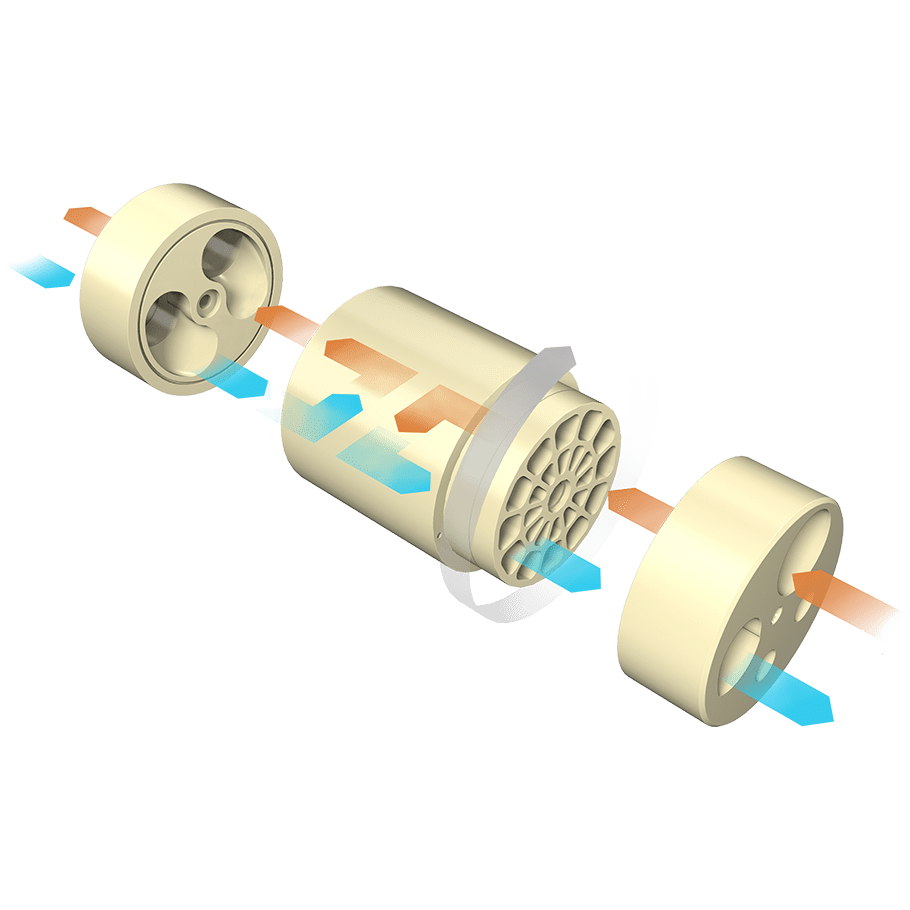

How it Works

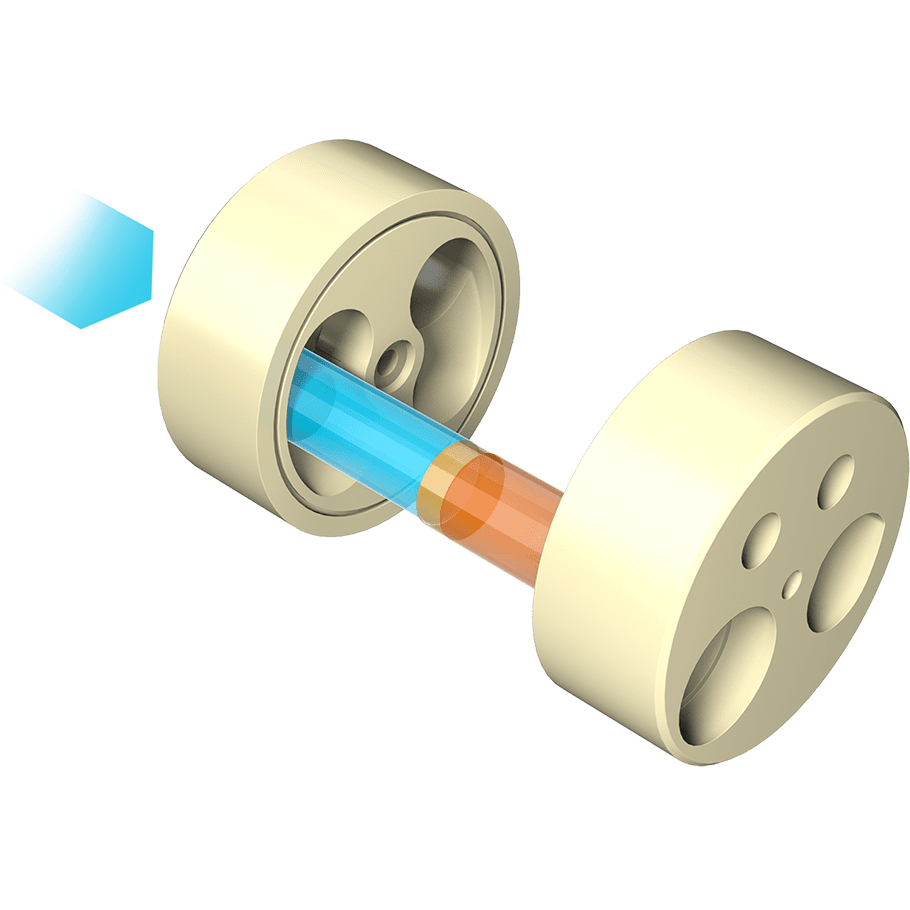

01

Low-pressure seawater or wastewater enters the PX rotor duct and is sealed. The high-pressure reject brine from the membrane enters the PX from the opposite side.

The high-pressure brine rotates the duct, transferring hydraulic energy to the low-pressure seawater or wastewater. The high-pressure fluid in the duct is then sealed.

Both fluid streams exit the PX separately. The rotor duct charges and discharges as the pressure exchange repeats, fluctuating between sealed and pressure exchanger phases .

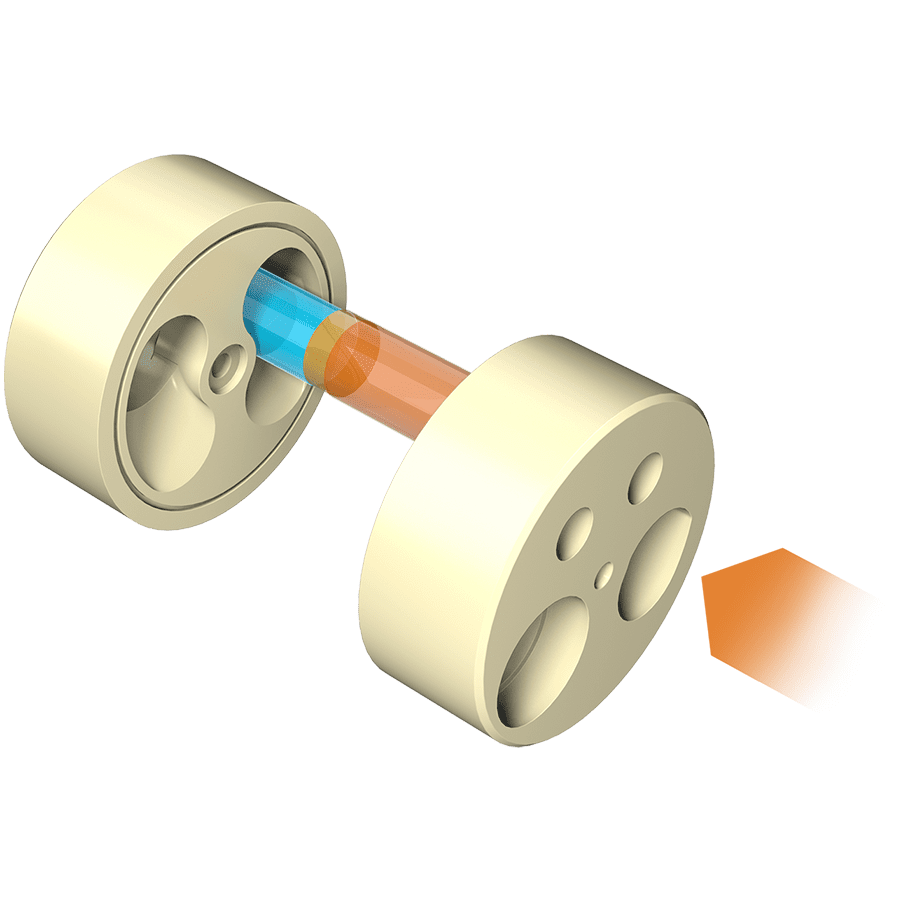

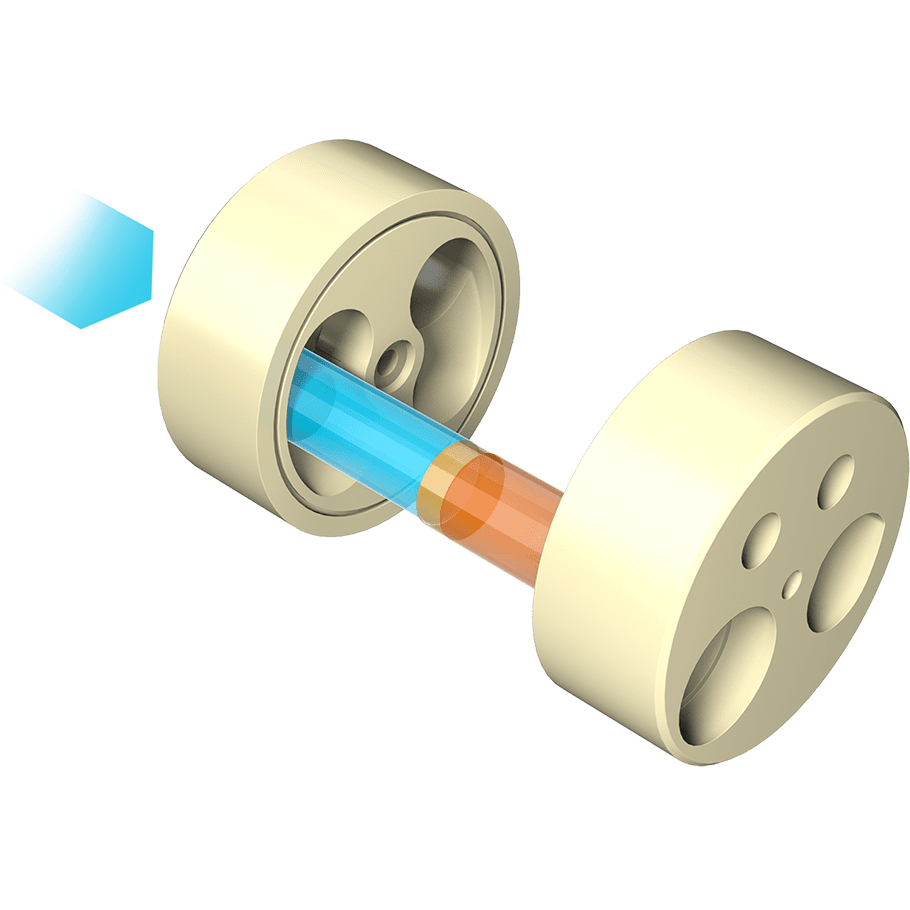

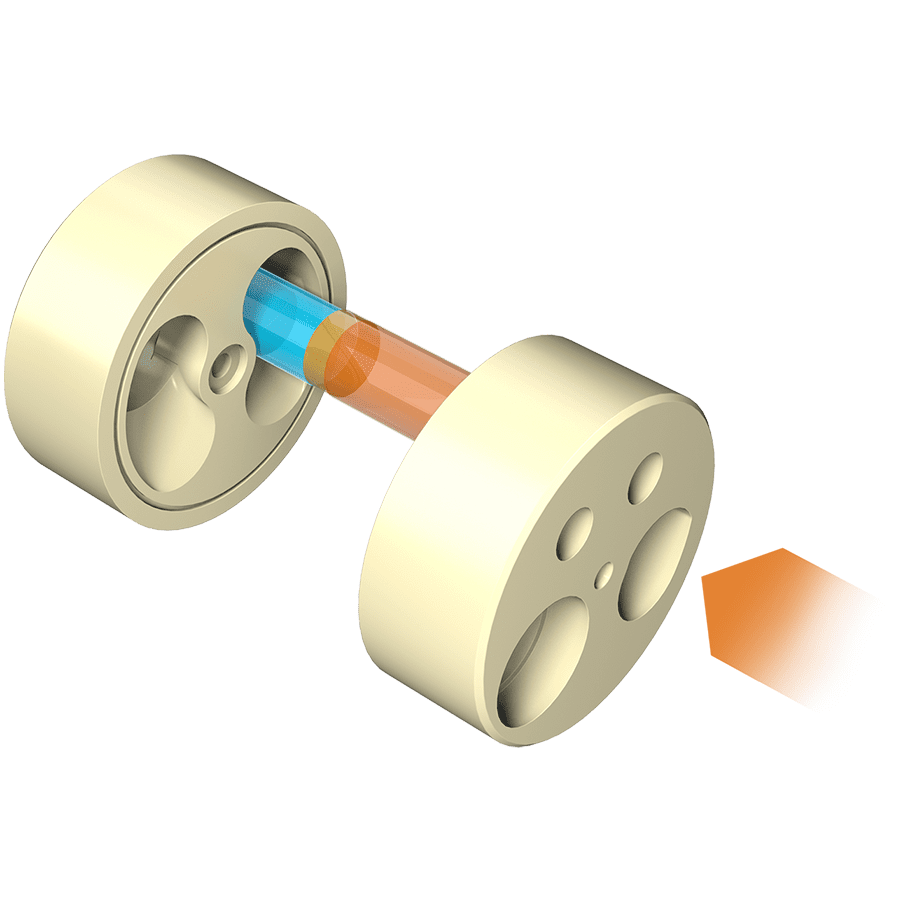

01

Inside the PX, the top half of the rotor acts as a compressor, drawing in low-pressure vapor and using the column of high-pressure fluid to compress the vapor and discharge it back to the system to do more work.

The bottom half of the rotor acts as an expansion valve, bringing in the high-pressure fluid from the gas cooler and allowing it to expand before discharging it out to the flash tank.

The pressure transfer provides expansion and free compression, operating similarly to a high-pressure valve and compressor within a CO2 system.

Innovation

Innovation and continuous improvement are at the core of our business, which began with a major technological leap forward over 30 years ago that resulted in the PX® Pressure Exchanger®. Since then, the PX has become the gold standard energy recovery device (ERD) in desalination, and we continue to develop our products and services with the goal of delivering solutions that our customers truly need.

PX Q400

Our most efficient, highest-capacity PX for seawater reverse osmosis desalination

The PX Q400 offers best-in-class performance from our industry-leading PX technology. Delivering energy and cost savings, the PX Q400 offers the lowest projected life cycle cost of any proven ERD for seawater reverse osmosis (SWRO) desalination, thanks to high performance and lower maintenance. The PX Q400 provides superior performance from the most trusted ERD in desalination – enhancing efficiency, capacity, reliability, and value. At 77 dB, the PX Q400 is one of the quietest ERDs on the market.

PX G1300®

Energy efficiency for CO2 refrigeration, simplified

The PX G1300 utilizes proven pressure exchanger technology to improve system performance by reducing energy costs, increasing cooling capacity, and increasing energy efficiency, especially at high ambient temperatures. *

By boosting energy efficiency, new system designs may also reduce or eliminate some components, offsetting capital expenses.

Its simple design and precision manufacturing ensure that the PX G1300 can be seamlessly integrated into existing and new high-pressure CO2 systems.